Heat transfer printing is a method of branding that is commonly used in the promotional gifts and clothing industry. It involves printing a design onto transfer paper, and then applying the design to the promotional item using heat and pressure.

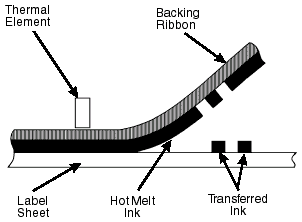

The process starts by creating a digital image of the design that is to be printed. This image is then printed onto transfer paper using a specialized printer. The transfer paper is then placed onto the promotional item, and heat and pressure are applied using a heat press or other specialized equipment. The heat and pressure cause the ink on the transfer paper to bond with the fabric of the promotional item, resulting in the final printed design.

Heat transfer printing is a fast and cost-effective method of branding, and it is suitable for a wide variety of promotional items, including t-shirts, bags, hats, and other types of clothing. It is also a good choice for full-colour printing, as it allows for the creation of complex and detailed designs.

However, heat transfer printing is not as durable as other branding methods, such as screen printing or embroidery. The prints may fade or peel over time, especially with frequent washing or wear. Therefore, it is best suited for promotional items that will not be subjected to heavy use or harsh conditions.

Advantages of heat transfer printing:

-

Heat transfer printing is capable of detailed designs, and it can be used to print on a variety of promotional items, including t-shirts and bags.

-

Good turn-around time: Heat transfer printing is a fast process, and it is possible to produce large quantities of promotional items in a short period of time. This is especially useful for companies that need to meet tight deadlines or have last-minute branding needs.

-

Shows small words and fine detail better than embroidery: Heat transfer printing is capable of producing very fine detail, making it ideal for printing small text or intricate designs. In contrast, embroidery may not be able to reproduce small details as clearly.

-

Can have shading to a degree: Heat transfer printing allows for the creation of gradations of colour, which can be used to create more nuanced and subtle designs. However, there are some limitations to the use of shading, and it may not be suitable for all designs.

Limitations of heat transfer printing:

-

Some items cannot be heat transfer printed: Some materials, such as those that are too soft or too uneven, may not be suitable for heat transfer printing.

-

Rough surfaces may not print correctly: The texture of the item being printed on can affect the final result. A rough or uneven surface may make it difficult to produce a smooth and even print.

-

Cannot brand on seams & zips: It is not possible to print on seams or zips, as the transfer paper may not lay flat on these areas.

The History of Heat Transfer Printing

Here is a little bit more about where this branding method came from.

This technique has been used for decades to create a wide variety of items, including t-shirts, hats, bags, and even ceramic tiles.

The history of heat transfer printing can be traced back to the early 20th century, when the first heat press machines were invented. These early machines were primarily used in the textile industry to print patterns and designs onto fabrics.

One of the earliest forms of heat transfer printing was the "hot stamping" process, which was developed in the 1920s. This process involved using a heated die to press a design onto a substrate, such as a piece of fabric. The die was heated by an external heat source, such as a gas burner, and then pressed onto the substrate to transfer the design.

In the 1960s and 1970s, heat transfer printing technology advanced with the invention of the heat press machine. This machine used a combination of heat and pressure to transfer designs onto a wide variety of substrates, including items of clothing, utility items and as broad as on ornaments and a wide range of decorative artwork. The heat press machine became increasingly popular in the 1980s and into the 1990s, as it allowed for faster and more efficient production of printed items.

With the advent of digital printing technology, heat transfer printing has evolved further albeit with adaptations. Today, digital heat press machines use computer-controlled heat and pressure to transfer designs onto substrates with great precision. This has opened up new possibilities for customizing products, as well as creating new applications for heat transfer printing.

The process of heat transfer printing is still a versatile and widely used method of creating custom printed items. Over the years, it has undergone significant technological advancements and has become increasingly popular in various industries. With the ongoing developments in digital printing technology, heat transfer printing will continue to be a valuable tool for creating personalised products and provides a valuable option for many applications