Pad printing is a printing process that involves transferring ink from a printing plate to a rubber pad, and then from the pad to the surface of the product being printed. It is often used for printing on irregular or curved surfaces, or for printing small or detailed designs.

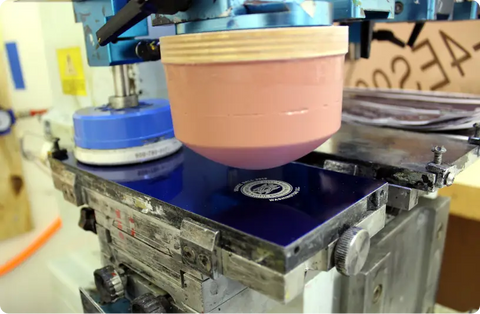

In the pad printing process, a printing plate, also known as a cliché, is created by etching a design into a metal or plastic plate. The plate is then attached to a printing press, and ink is applied to the etched design. A rubber pad is then pressed onto the ink on the plate, which picks up the ink and transfers it to the pad.

The pad is then pressed onto the surface of the product being printed, transferring the ink from the pad to the product. This process can be repeated multiple times to build up the desired thickness of ink on the product.

Pad printing is a popular method for printing on a wide range of products, including promotional items, toys, automotive parts, and medical devices. It is known for its ability to print small and intricate designs, as well as its versatility in printing on different types of materials and surfaces.

Preparing Artwork for The Pad Printing Method

- The artwork should be in the format of a Vector PDF - ask your designer for this.

- The colours on the artwork should be well separated. Pad printing does not work well with complex colours that blend into each other.

- Each colour will have a separate "plate" which is a physical template and this "plate" has a cost element called "setup-up" costs needed to manufacture the plate.

Advantages Pad Printing & When to Use Pad Printing

- Pad printing is economical when printing 1-2 colours

- Pad printing can be used to brand uneven/rounded surfaces

- Pad printing is a quick branding method with good turnaround times

The Limitations of Pad Printing

-

Pad printing is only practical for up to four colours maximum,no shading or complex colours (solid colours only)

- Pad Printing has a minimum height for text in lowercase which is 1mm high

- Only certain items can be branded with pad printing where access to the surface area is ideal for this methods - items like pens, bottles and so forth.